Introduction

Embarking on procurement management transformations? “A Beginner’s Guide to One-Stop Sourcing: “Simplifying and Streamlining Your Procurement Process!” exposes the immense sense of difficulty that could be encountered in this case. It also discloses about the ways the supply chains are optimized through sourcing from China besides other advantages like low cost, faster operations and many others. It is the hope of this treaty that your grasp on strategic sourcing is laid down thus giving your business the competitive edge.

What Is One-Stop Sourcing?

One-stop sourcing is one specific branding concept and is specifically related to aggregate procurement while sourcing from china. It entails a sole platform or service provider while a multitude of needs is being served. The idea here is to make interactions easier, to overcome supply chain problems and to facilitate a faster and more efficient flow of the supply chain in general. Companies will save time by end of the vendor or supply chain management and ensure consistent quality. Implementation of a supplier consolidation technique can facilitate efficiency, propel costs down, and hasten time to market response.

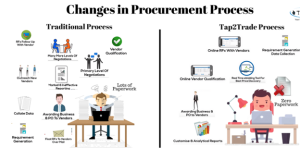

Why Is Streamlining Procurement Important?

– Efficiency Gains

Sourcing components from China enhances operational efficiency. It streamlines inventory with precise tracking. Advanced logistics systems reduce processing times. Automated procurement tools integrate seamlessly, optimizing order flows.

– Cost Reduction

Direct procurement from Chinese manufacturers cuts costs significantly. Negotiating deals on bulk orders lowers price points. Elimination of intermediaries means financial savings are immediate. Strategic sourcing optimizes budget allocation.

– Time Savings

Fast track shipping options from China slash delivery times. Real-time order tracking accelerates supply chain responsiveness. Streamlined customs procedures ensure quick clearance. Efficient logistics partnerships minimize delays.

– Supplier Consolidation

Consolidating suppliers to a few in China simplifies management. It ensures consistency in quality and delivery standards. Relationships strengthen over time, enhancing trust. Simplified communication channels speed up decision-making processes.

– Risk Mitigation

Strategic partnerships in China mitigate supply chain risks. Diversified sourcing strategies prevent bottlenecks. Robust quality control systems ensure product standards. Proactive

Monitoring detects potential disruptions early, enabling swift adjustments.

How Can One-Stop Sourcing Benefit Your Business?

– Cost Efficiency

Unitary sourcing instead of costly buying from elsewhere greatly decreases purchase costs. There is also an element of simplicity in that the negotiations can be concluded immediately, which in turn directly affects purchase prices. In case of bulk buying you are offered with an option of having the items at heavily subsidized price. Generally speaking, outlay decreases, therewith, promoting profit margins of the enterprise.

– Streamlined Operations

The adoption of one-stop approach complexity namely in the China reduces the whole operational procedures. It unites the vendors’ messages in a single resource that is free from administrative work. Inventory management requires less time and efforts. From the initial production to the final distribution all the processes go smoothly.

– Enhanced Quality

Quality consistency improves with one-stop sourcing from China. Single-source suppliers adhere to stringent quality checks. Product development standards align closely with business requirements. Customer satisfaction rates climb as a result.

– Agile Response

One-stop sourcing enables quicker adjustments to market demands. Chinese suppliers offer flexible production capabilities. Swift changes in product design or volume are manageable. Businesses stay competitive with rapid response times.

– Risk Control

Risk management strengthens with one-stop sourcing in China. Dependence on multiple suppliers decreases. Comprehensive audits ensure supplier reliability. Business continuity plans become more robust, mitigating potential disruptions.

What Should You Look for in a One-Stop Sourcing Partner?

– Reliability

Select partners in China who guarantee prompt delivery and quality control. A reliable source ensures 99.9% uptime with QC checks at stages 1, 20, 50. Review past performance records and client testimonials. Opt for those with less than 0.1% defect rates. Trust hinges on proven track records and precise, error-free logistics.

– Scalability

Choose sources capable of adjusting to volume changes. Ideal partners can handle order management from 100 to 10,000 units without delay. Assess their production capabilities and warehouse size. A scalable partner has multiple production lines and a 500,000 square foot storage area. They adapt swiftly to your growing demands.

– Flexibility

Flexibility means customized solutions and rapid response to changes. Select firms that offer product personalization and can shift schedules within 24 hours. Their systems should integrate seamlessly with yours, allowing for instant updates and modifications. A flexible partner in China responds to last-minute adjustments without compromising quality.

– Technological Edge

Prioritize partners with advanced R&D facilities and patent holdings. Look for a track record in innovation, with at least 50 patents to their name. These partners should offer exclusive access to the latest tech, including AI-driven logistics systems. A technological edge means staying ahead in competitive markets.

– Market Knowledge

Insist on a partner with deep insights into Chinese and global markets. They should have a decade of experience, at least, and connections with local suppliers and government. This knowledge translates into better sourcing strategies and cost efficiencies. Such a partner navigates market fluctuations with expertise, benefiting your supply chain.

– Support Services

Support services are crucial. Your sourcing partner must offer 24/7 customer support, multi-lingual assistance, and on-site help in China. Look for comprehensive after-sales service, including installation guidance and troubleshooting. These services ensure smooth operations and minimize downtime, enhancing overall satisfaction.

How to Evaluate Potential One-Stop Sourcing Solutions?

– Cost Effectiveness

Evaluate if sourcing from China maximizes value while minimizing expenses. The ideal partner offers competitive pricing for orders above 500 units without compromising quality. Compare unit costs across at least three suppliers. Ensure there are no hidden charges in logistics, customs, or handling. Optimal cost-effectiveness comes from transparent pricing and high-quality outputs.

– Integration Ease

Choose solutions that sync smoothly with your existing systems. The best options support plug-and-play integration and provide APIs for real-time data exchange. Test compatibility with your inventory and CRM software. A seamless integration process reduces setup time and eliminates the need for extensive training.

– Customization Level

Assess the provider’s ability to tailor products to your specifications. Your partner should offer customization for orders as small as 100 units. Review their portfolio for bespoke solutions in your sector. High customization levels mean products that closely fit your needs and distinguish your offerings in the market.

– Support Quality

Quality support ensures uninterrupted operations. Select partners offering 24/7 technical assistance is with a response time under 2 hours. Evaluate their support team’s expertise through customer feedback. Excellent support services resolve issues quickly, maintaining your business’s continuity and customer satisfaction.

– Supplier Network

A strong supplier network indicates access to diverse and quality resources. Investigate the depth and breadth of the partner’s network, covering at least 200 suppliers. A vast network enables sourcing rare components swiftly, ensuring your supply chain remains robust against disruptions.

– Scalability

Scalability is critical for growth. Ensure the solution can handle an increase from 100 to 10,000 units without efficiency loss. Evaluate their production capacity and logistics network. Scalable solutions adjust to your demand spikes, supporting expansion without additional investment in new sourcing partnerships.

– Security Features

Security safeguards your interests. Check for encryption in data exchange, IP protection policies, and compliance with international standards. A partner with robust security features protects your designs, data, and business integrity, minimizing risks in global trade operations.

Common Mistakes to Avoid in One-Stop Sourcing!

– Rushed Decisions

Only after a rigorous partnership filtering process can we are prudent to commit to such partnership avoiding the dilemmas. In a game of speed, frequently mistakes happen when it comes to defects or dependability in production. Scrutinize all aspects of any China-based sources that are for capability, good reviews, and quality of output.

Such approach will provide groundwork to sensitive other members towards the idea of strategic cooperation which will result in less probability of taking premature undertakings that may expose partner countries to many risks.

– Overlooked Costs

You will need to expect all kinds of expenses beyond raw product prices if buying from China. Invisible costs like shipping, re-suppository fees, and import taxes may proportionately heighten the costs. Ask for comprehensive quotes that will address all the anticipated costs to avoid these hassles affecting your financial limits. No hidden deals and budgets are taken a step further, avoiding the operational breakdowns. The occurrence of budget overruns is therefore, a thing of the past.

– Ignored References

The role of customers’ previous experience in the value chain is underestimated which makes the oversight come inevitably. Ask for references of colleagues, and train workers to select suppliers with whom communication is efficient and all requirements are met.

The information which we gain by creating links with partners of the past helps us with answers of many questions and suggests what matters are better left to be avoided and what might prove useful wisely.

– Skipped Trials

This procedural guile that disregards the step of sample testing endangers the integrity of consistency and the quality. Trials supply with samples of your trial batches though prototypes to ensure that product specifications and quality meet your envisaged standards.

First tests avoid big scale failures whose consequences are negative and give rise to confidence in product range and surete in sales.

– Misalignment

Appraise if the objectives are synchronized with your Chinese partner’s skill set. It can be difficult to satisfy the need for something and being rejected because our ideas do not match what is needed from the other party’s end and can jeopardize activities.

Develop definitive communication channels and compact contractual claims specifying main functional obligations based on each stakeholder’s abilities and competencies.

How to Implement One-Stop Sourcing in Your Business?

– Define Needs

Awareness that Chine is a native language of China, while plentiful for researchers is of little help to volunteer translators. Start with a clear list: elements, materials, quantities. Identify must-haves vs. nice-to-haves. This mechanism of action enables one to direct the resources. It is very vital to get knowledge about the market in which you resell products.

– Set Goals

Develop measurable goals for your product cost, quality and delivery timeline. Goals must be SMART: Objective and output oriented, while being precise, ambitious, doable, relevant, and specified in both time and time-scale. You might state that the aim is cutting procurement costs to 15 units by means of negotiated rates and bulk purchases.

– Choose Carefully

Selecting suppliers is pivotal. Does a little research about their quality, reliability, and if their capacity is enough to support weight that you produced. Look into the strengths and weaknesses by means of the evaluation projects such as reviews and case studies. Rating suppliers having certifications like ISO 9001 as the first preference.

– Plan Integration

Ingrain your supply chain the way you want is an utmost necessity. Develop a timeline for each phase: from anletesting to the final challenge of large-scale product coordinate together with transportation partners to make certain that shipment dates are met. Continually remind and inform internal staff on the timelines and the requirements.

– Monitor Progress

Make sure all your actions are accurate. The main supplier interaction is checking up with them in a timely manner. Set up a system where after every three months, there is a look back to determine if the targets have been met. Modify strategies in case the efficiency of them requires, which is based on feedback and results description.

Overcoming Resistance to Change in Procurement Processes!

– Clear Communication

Effective communication is crucial when shifting to sourcing from China. Clear objectives and benefits must be shared across teams. Transparent discussions alleviate fears and build support. Regular updates keep everyone aligned and motivated.

– Training Offered

Providing comprehensive training ensures smooth transition to new procurement practices. Tailored sessions on sourcing from China equip staff with necessary skills. Knowledge builds confidence, reducing resistance. Continuous learning opportunities maintain engagement.

– Early Wins

Securing early successes boosts morale and support for new sourcing strategies. Demonstrating quick benefits from Chinese partnerships motivates further adoption. Celebrating these achievements reinforces positive outcomes. It paves the way for broader acceptance.

– Continuous Feedback

Implementing a system for ongoing feedback encourages adaptation and improvement. Listening to concerns about sourcing from China helps identify issues early. Responsive adjustments enhance buy-in from all levels. This approach fosters a culture of collaboration and innovation.

– Adapt Strategy

Flexibility in strategy allows for adjustments based on real-world experiences. Adapting procurement methods to better suit sourcing from China ensures sustainability. Learning from each step refines processes. Tailored approaches minimize resistance and optimize results.

Measuring the Success of Your One-Stop Sourcing Strategy with Larkser!

– Savings Achieved

Tracking savings is essential in evaluating the success of sourcing from China with Larkser. Regular comparisons of cost before and after implementation highlight efficiency gains. Precise metrics on reduced spending validate the financial impact. Achievements in cost reduction reflect strategic sourcing effectiveness.

– Process Efficiency

Assessing process efficiency reveals the operational benefits of a one-stop sourcing strategy. Shorter lead times and fewer administrative tasks indicate streamlined operations. Monitoring order fulfillment rates and inventory turnover provides insights. Improved metrics signify operational optimization with Larkser.

– Supplier Performance

Evaluating supplier performance is key to understanding the value of partnerships in China. Metrics such as delivery punctuality, product quality, and responsiveness offer a clear picture. Regular assessments ensure suppliers meet expectations. High performance levels from suppliers confirm the strength of the sourcing strategy.

– Stakeholder Satisfaction

Stakeholder satisfaction gauges the internal impact of the one-stop sourcing strategy. Surveys and feedback from teams involved in procurement processes measure contentment. Increased satisfaction scores indicate successful integration and acceptance. Positive feedback from stakeholders underscores the strategy’s effectiveness.

– Innovation Rate

The rate of innovation reflects the strategic advantage gained through sourcing with Larkser. Tracking need the introduction of new products and processes measures progress. Collaboration with Chinese suppliers often leads to innovative solutions. An uptick in innovation signifies a competitive edge, bolstering market position.

Conclusion

“A Beginner’s Guide to One-Stop Sourcing: “How do you improve your Procurement processes and make them effective when sourcing from China?” defines the starting point for getting on the right track in sourcing. It reveals a way for efficiency in cost structure and operational excellence. When looking for breakthrough insights, strategic advantages, you can always check LARKSER website. Start your mastering procurement-streamlining path immediately.